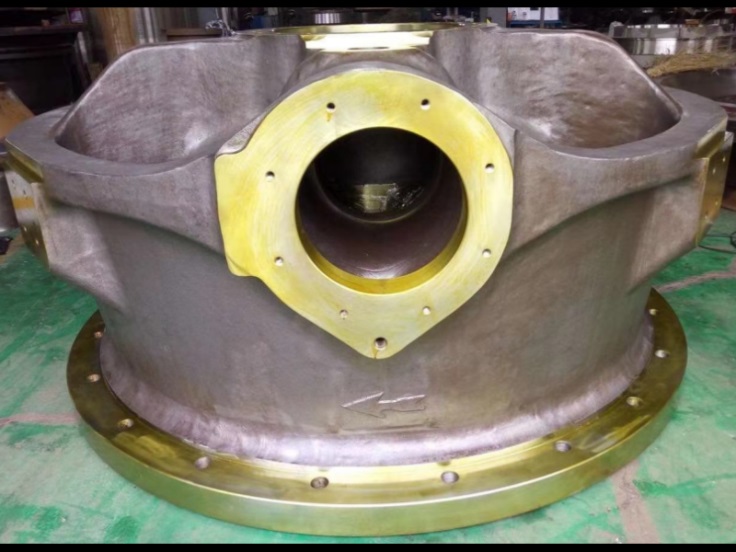

1. The Sandvik Bottom Shell is made of high strength and abrasion resistant material that can withstand high loads and severe impacts. They can keep the integrity and stability of the structure and prolong the service life during the crushing process.

2. Sandvik Bottom Shell adopts precise manufacturing process and high precision machining equipment to ensure the precise size of parts and excellent surface quality. This allows the bottom shell to work closely with other parts, providing a stable crushing effect.

3. The Sandvik Bottom Shell is designed for ease of installation and maintenance. They are typically Modular design and can be removed and replaced quickly, reducing downtime and maintenance costs.

Send Email

More

2. Sandvik Bottom Shell adopts precise manufacturing process and high precision machining equipment to ensure the precise size of parts and excellent surface quality. This allows the bottom shell to work closely with other parts, providing a stable crushing effect.

3. The Sandvik Bottom Shell is designed for ease of installation and maintenance. They are typically Modular design and can be removed and replaced quickly, reducing downtime and maintenance costs.