- Home

- >

- Products

- >

- Sandvik Bottom Shell

- >

Production equipment 🔗

The main equipment of our factory includes five-meter CNC vertical lathe, slotting machine, three-zero lathe, eight-point rocker, Hangzhou crane, 160 boring machine, internal milling machine and other equipment.

There are large and medium sized Vertical lathe 125、80、60、20Horizontal lathe 160、90、60 Floor type borer 100、80、50 Radial drill Various processing 40 equipment.

In the processing of production, not only to the high quality can be ensured by reasonable arrangements, as well as a high efficiency, all equipment including vulnerable parts,spare parts,product parts are processed by our own production.

Exhibition photos 🔗

FAQ 🔗

1. Question: Will we provide pre-sales service?

Answer: ShanYo is composed of experienced experts, and we will provide suitable solutions in a timely manner according to customer requirements.

2. Question: Is our after-sales service excellent?

Answer: ShanYo's skilled technical personnel can assist with on-site installation, debugging, and training as required. This will enable customers to optimize the performance of their new factory. Dimensional drawings along with service requirements will be provided before equipment delivery. This will enable customers to prepare the venue and allow them to start production in a timely manner.

ShanYo has sufficient spare parts inventory and their efficient service personnel will ensure that any necessary parts will be dispatched without delay. Depending on the urgency of the situation, spare parts can be delivered by air, sea, or express delivery. We encourage customers to keep their critical spare parts, such as crusher blades and screens, to ensure optimal machine condition and performance.

3. Question: Will we provide technical support?

Answer: ShanYo provides sufficient hardware resources, especially for large-scale production lines, where customers can install, debug, and inspect before delivery.

Packing of Cone Crusher Parts 🔗

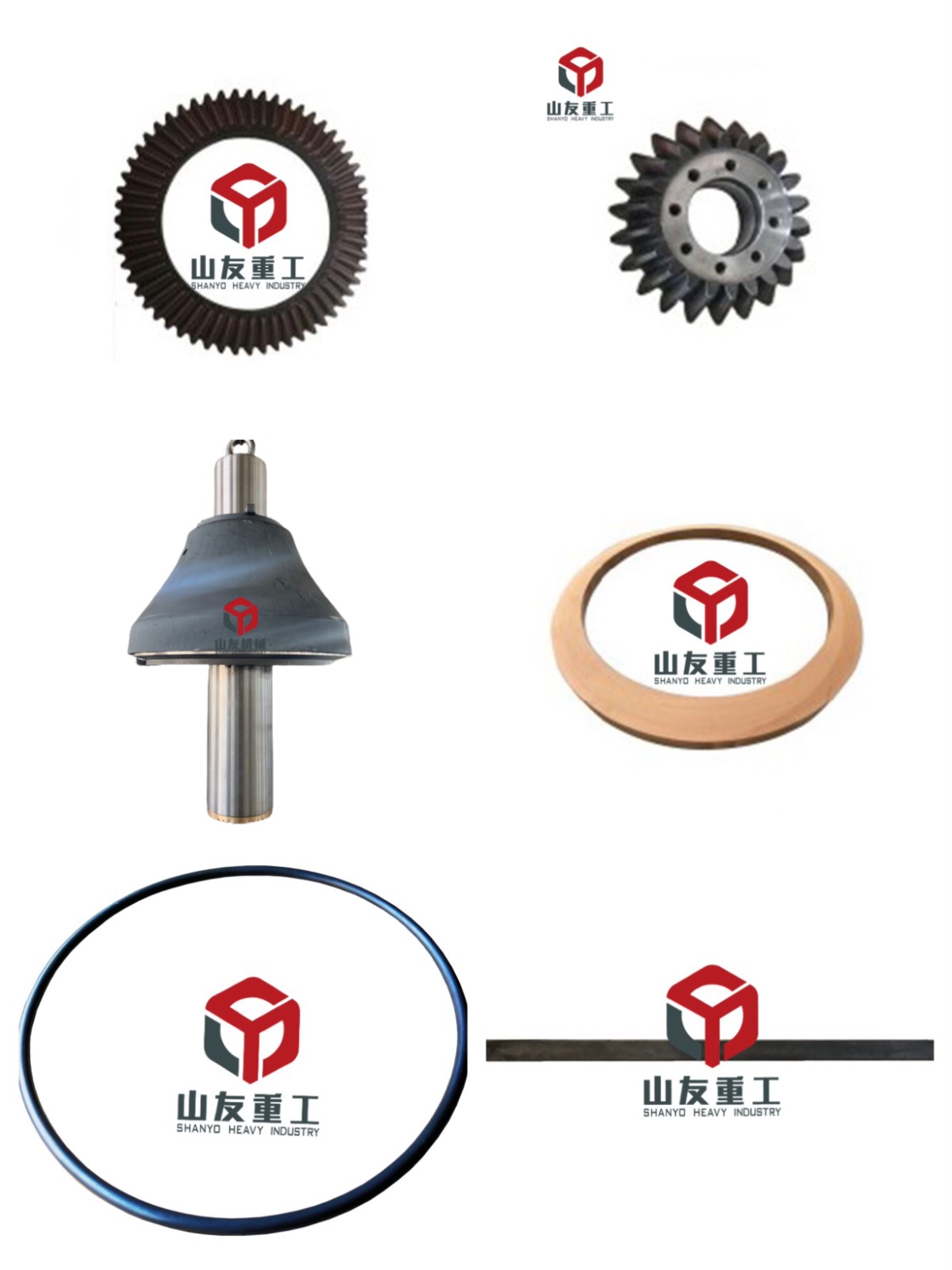

Other parts of Cone Crusher