Factory Introduction 🔗

Our factory has a history of more than 20 years, covering a total area of 36000 square meters, and equipped with advanced production equipment. In our factory, we have produced more than 1000 sets of mining equipment. With our reliable quality assurance and high-quality after-sales service, we have won the unanimous praise of the majority of users.

Our company's products mainly include mining equipment such as cone crushers, rotary crushers, jaw crushers, ball mills, etc. The equipment specifications range from large to small, with complete models. At present, there are many categories of cone crushers in our company's main core products. In addition to the classic spring crushers, our company's subsequent main HP/MC multi cylinder cone crushers and CH-CS/SC single cylinder crushers are all manufactured according to the imported original drawing 1:1, which can replace the original imported crushers. Due to their high cost-effectiveness and timely after-sales service, they have received recognition and support from many customers. (For specific details, please refer to the product information on the official website)

Our company also has long-term stock of accessories and vulnerable parts, such as Symons, Sandvik, and Mesto, which can be interchanged with original accessories. Simply provide the original part number to produce, and the materials and dimensions meet the original quality. This allows users to use and purchase with confidence before and after purchase, ensuring production.

Ongoing Feedback Service

ShanYo is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude ShanYo makes it a point that past sales are just as important as the future. Because of this ShanYo will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.

Our goal is to provide minining equipment of excellent quality and reliability, in order to establish a reputation and relationship with our customers which will keep them customers for life.

We have a strict quality control system in place throughout the entire production process, so our products are all of the highest quality and reliability.

If you have a need for any mining equipment, or related spare parts, please feel free to contact us. We are dedicated to serving each of our customers to their complete satisfaction.

Certifications 🔗

Product advantages of cone crusher parts

1、 Improved production

2 、More accurate product sizing

3 、Better wear metal utilization and lower discard weight

4 、Longer wear part life

5 、Lower overall operating costs

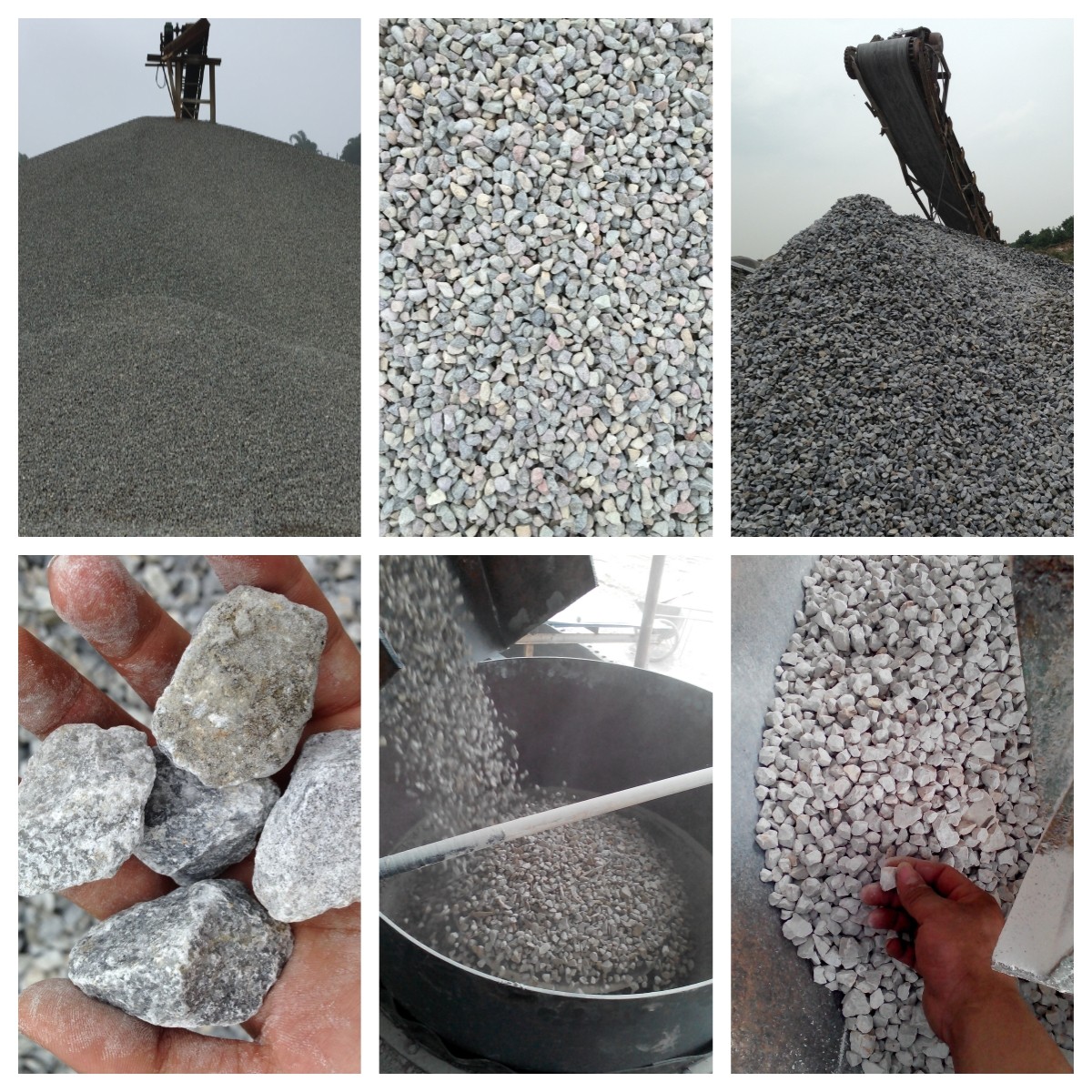

On site photos