Sandvik Crusher Parts Product Information

Brand: Sandvik parts

Product Origin: Made in China

Packaging: all in wooden crates (if there are special circumstances, special packaging will be taken)

Certification: CE, ISO 9001:2000, ISO 9001:2008

Standard:AISI, ASME, BS, ANSI, JIS, GB, GOST, ASTM, DIN

Surface Treatment:Spray-Paint

Manufacturing Process:Forging

Delivery time: 1 week-5 weeks, according to the actual situation.

Supply ability: We are a direct source factory, and long-term spare parts, wearing parts, so that users can rest assured that both before and after the purchase, to protect the user's production.

Place of delivery: Shenyang, Liaoning Province, China

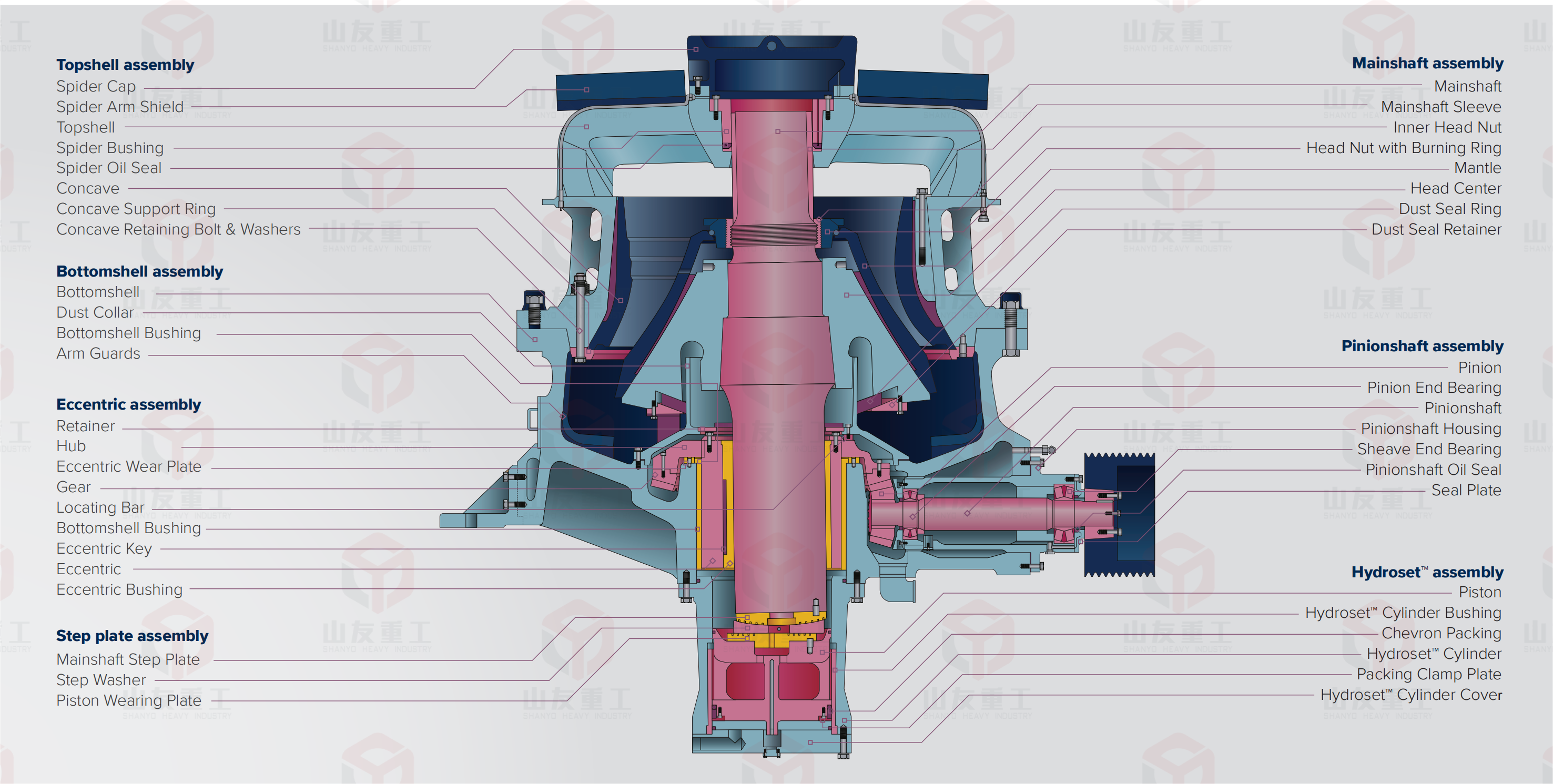

Sandvik Crusher Parts

| Sandvik Parts | |||||

| Sandvik Inner Nut | Sandvik Bearing | Sandvik Top Cap | Sandvik Counterweight | Sandvik Piston | Sandvik Dust Ring |

| Sandvik Bowl Liner | Sandvik Dust Cover | Sandvik Main Shaft assembly | Sandvik Eccentric assembly | Sandvik Countershaft Box | Sandvik Pinion Shaft |

| Sandvik head Nut | Sandvik Head centre | Sandvik spider Bushing | Sandvik Mainshaft sleeve | Sandvik Hydroset cylinder | Sandvik Gear and Pinion |

| Sandvik Topshell | Sandvik Bottom Shell | Sandvik bushing parts | Sandvik Oil Seal | Sandvik Step washer | Sandvik Arm liner |

| Sandvik Out head Nut | Sandvik Eccentric Bushing | Sandvik Mainshaft step | |||

Our company's products mainly include mining equipment such as cone crushers, rotary crushers, jaw crushers, ball mills, etc. The equipment specifications range from large to small, with complete models. At present, there are many categories of cone crushers in our company's main core products. In addition to the classic spring crushers, our company's subsequent main HP multi cylinder cone crushers and CH-CS single cylinder crushers are all manufactured according to the imported original drawing 1:1, which can replace the original imported crushers. Due to their high cost-effectiveness and timely after-sales service, they have received recognition and support from many customers. (For specific details, please refer to the product information on the official website)

Our company also has long-term stock of accessories and vulnerable parts, such as Symons, Sandvik, and Metso, which can be interchanged with original accessories. Simply provide the original part number to produce, and the materials and dimensions meet the original quality. This allows users to use and purchase with confidence before and after purchase, ensuring production.

Our Services

Don’t just repair your equipment, improve your machines with our optimised spare cone crusher parts.

Price, quality and customer service

We offer competitive pricing, improved design and excellent service, ensuring you get the best possible return on your investment. We cover a wide range of cone crusher replacement parts for Sandvick crusher parts for Hydrocone and Superior Crushers, including the head center, arm shield, burning ring and more.

In many cases, we have improved the design of the OEM spare parts to enhance durability and performance. From the older Allis-Chalmers® and Svedala® models, to the modern Sandvik® Superior™ crusher replacement parts. We carry premium components for your equipment. No matter your need, we have the parts. Price, quality and customer service are all important factors when replacing parts for your Sandvik Crushers. We offer superior customer support, high-performance parts and competitive prices.

Our priority is supplying you with high-quality parts and high-quality service. All the crusher replacement parts are supported by our commitment to rigorous quality standards. Our customer support team is ready to help you find a part number, check inventory or simply answer technical questions.

We offer cost effective Sandvik Hydrocone and Superior cone crushers parts.

Replacing parts is a drag on your business. Maintenance down time eats away at your throughput, and replacement components can be a significant investment — especially when they don’t last very long. Our premium solutions for Sandvik, Hydrocone and Superior Crushers means you get improved parts backed by thorough quality checks. Keep your machines running faster and longer with our replacement parts.

Precautions for using Sandvik crusher parts

Before replacing sandvik parts, make sure the crusher is shut down and the power supply is cut off.

Use professional tools and equipment for replacement to avoid artificial damage to parts or safety accidents.

After replacing sandvik crusher parts, comprehensive functional testing and debugging should be carried out to ensure that the crusher operates normally.

Regularly check the wear degree of the sandvik parts and replace it in time to ensure the stable operation of the crusher.

Introduction to sandvik crusher parts

1、Sandvik cone crushers are suitable for a variety of quarrying and mining applications, producing products including aggregates for concrete and asphalt.

2、Sandvik parts for mobile cone crushers offer large crushing ratios and minimal fines production, making them an ideal solution for secondary and tertiary crushing.

3、Sandvik cone parts for mobile cone crushers offer large crushing ratios and minimal fines production, making them an ideal solution for secondary and tertiary crushing.

4、Sandvik parts are of high quality, ensuring high performance throughout the life of the machine.

If you are interested in our products, you can always leave a message to us, we will be the first time to reply to your message, looking forward to your inquiry!

Our factory not only has sandvik parts but also metso parts, symons parts and cone crusher parts for you to choose.

Click below to learn more about cone crusher products:

Advantages of Sandvik crusher parts

1. Our sandvik crusher parts has high wear resistance: Made of high-quality materials and treated with special processes, it has excellent wear resistance and can withstand the wear caused by high-intensity working environments.

2. Our sandvik parts has strong stability: reasonable structural design and precision processing ensure that the bearing replacement parts have good stability and reliability, and reduce vibration and noise when the crusher is running.

3. Our sandvik crusher parts are easy to replace: Bearing replacement parts are designed in standard sizes and are fully compatible with original parts. They are easy and quick to replace, saving maintenance time and costs.

4. Our sandvik parts has a wide range of applications: It is suitable for various jaw crusher brands and models, and is widely used in gravel operations in mining, construction, highway and other industries.

cone crusher parts photos