- Home

- >

- Products

- >

- Vibrating Feeder

- >

Product advantages of Vibrating Feeder

1、Liner Vibrating Feeder Machine Vibrating Screen Shaker Feeder is also called vibration feeder. In the production process, the vibrating feeder can uniformly, regularly and continuously feed the massive and granular materials from the storage bin to the receiving device.

2、 In the sand and gravel production line, Liner Vibrating Feeder Machine Vibrating Screen Shaker Feeder can continuously and evenly feed the crushing machinery and coarse screen the materials.

3、Liner Vibrating Feeder Machine Vibrating Screen Shaker Feeder is widely used in the crushing and screening combined equipment in metallurgy, coal mine, mineral processing, building materials, chemical industry, abrasive and other industries.

4、Stable vibration, reliable operation and long service life.The adjustment is convenient and stable, and the flow can be changed and controlled at any time by adjusting the excitation force.

5、The vibration motor is the excitation source, with low noise, low power consumption, good adjustment performance and no material impact.

6、Simple structure, reliable operation, convenient installation and adjustment, light weight, small size and convenient maintenance.Enclosed structure can be adopted to prevent dust pollution.

7、The machine can uniformly, quantitatively and continuously feed massive and granular materials from the storage bin into the receiving device, and can continuously and evenly feed the crusher in the sand and gravel production line, and coarse screen the materials.

8、 It is widely used in crushing and screening production lines in metallurgy, building materials, chemical and coal mines, abrasive and other industries.

Technical parameter of Vibrating Feeder

| Model | Size of trough(mm) | Feeding size (mm) | Motor power (kw) | Capacity (t/h) | Overall dimension (mm) |

| ZSW-650×2300 | 650×2300 | ≤300 | 1.1×2 | 80 | 2300×1360×780 |

| ZSW-850×3000 | 850×3000 | ≤400 | 7.5 | 80-120 | 3110×1800×1600 |

| ZSW-960×3800 | 960×3800 | ≤500 | 11 | 120-210 | 3850×1950×1630 |

| ZSW-1100×4200 | 1100×4200 | ≤580 | 15 | 200-430 | 4400×2050×1660 |

| ZSW-1100×4900 | 1100×4900 | ≤580 | 15 | 280-500 | 5200×2050×1700 |

| ZSW-1300×4900 | 1300×4900 | ≤650 | 22 | 450-600 | 5200×2050×1750 |

| ZSW-1300×6000 | 1300×6000 | ≤700 | 30 | 450-680 | 6100×2350×1750 |

| ZSW-1500×6000 | 1500×6000 | ≤1000 | 37 | 400-800 | 6100×2350×1860 |

Factory Introduction 🔗

Our factory has a history of more than 20 years, covering a total area of 36000 square meters, and equipped with advanced production equipment. In our factory, we have produced more than 1000 sets of mining equipment. With our reliable quality assurance and high-quality after-sales service, we have won the unanimous praise of the majority of users.

Our company's products mainly include mining equipment such as cone crushers, rotary crushers, jaw crushers, ball mills, etc. The equipment specifications range from large to small, with complete models. At present, there are many categories of cone crushers in our company's main core products. In addition to the classic spring crushers, our company's subsequent main HP/MC multi cylinder cone crushers and CH-CS/SC single cylinder crushers are all manufactured according to the imported original drawing 1:1, which can replace the original imported crushers. Due to their high cost-effectiveness and timely after-sales service, they have received recognition and support from many customers. (For specific details, please refer to the product information on the official website)

Our company also has long-term stock of accessories and vulnerable parts, such as Symons, Sandvik, and Mesto, which can be interchanged with original accessories. Simply provide the original part number to produce, and the materials and dimensions meet the original quality. This allows users to use and purchase with confidence before and after purchase, ensuring production.

Ongoing Feedback Service

ShanYo is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude ShanYo makes it a point that past sales are just as important as the future. Because of this ShanYo will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.

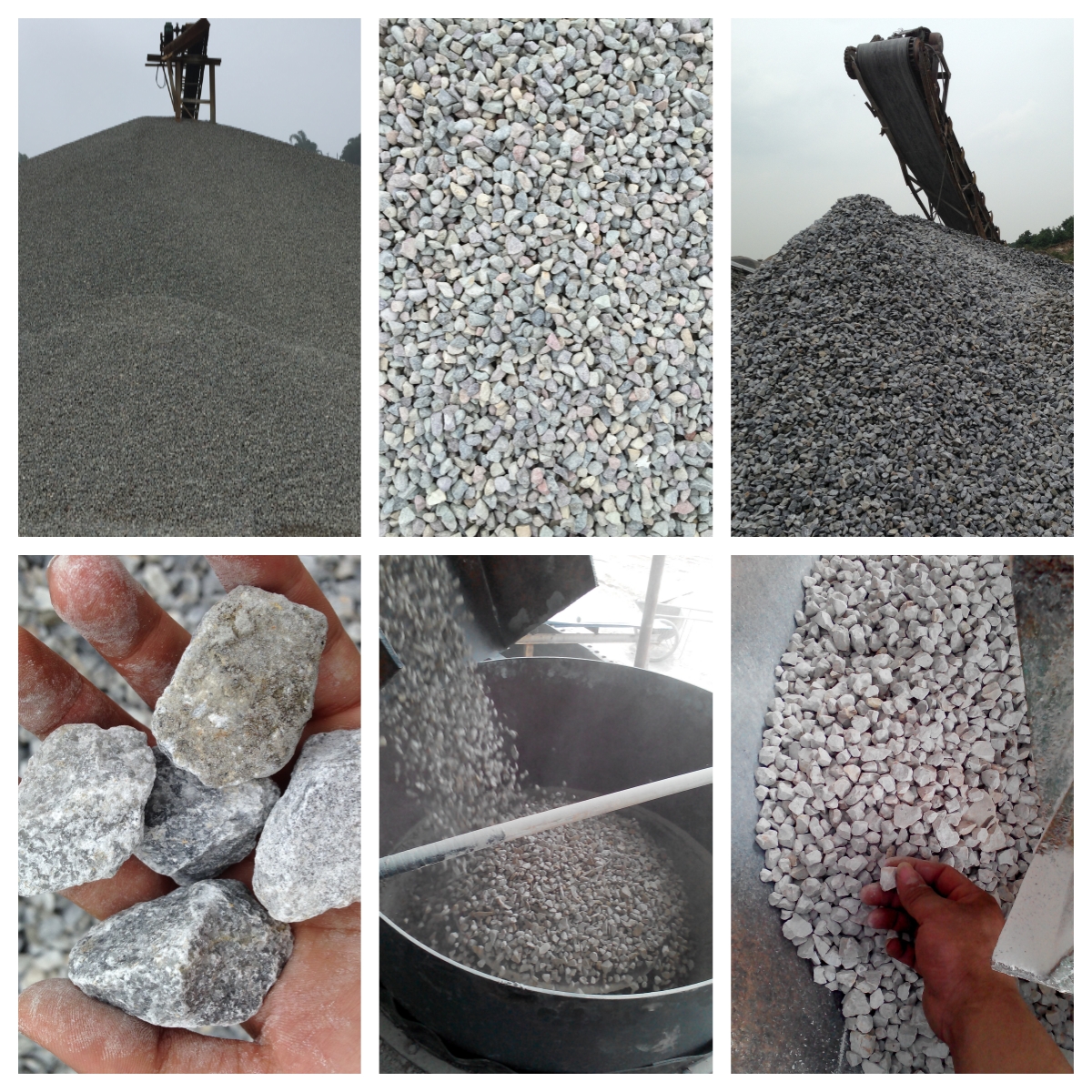

On site photos

FAQ 🔗

Shenyang Shanyo Heavy Industry Machinery Manufacturing Co., Ltd., founded in 1996, is located in Shenyang, Liaoning Province, the old heavy industry base in northeast China. It is the first batch of factories producing and manufacturing mining machinery and equipment.

Our company mainly produces various types of cone crusher, jaw crusher, rotary crusher, impact crusher, vibrating screen, feeder, ball mill and other products. At the same time, we also produce various equipment parts to provide customers with all-round services.

After purchasing the equipment, we will assign special after-sales service personnel free of charge to arrive at the site to guide customers in installation, commissioning, trial operation and on-site training of operators. The equipment is subject to three guarantees, and the warranty period is one year. After-sales service is the guarantee of long-term cooperation between the company and users. Our company has a professional after-sales service team with strong technical force. If the equipment fails during the warranty period, our company will arrange after-sales service personnel to arrive at the site as soon as possible to eliminate the fault and ensure the normal production of users.

We have not only advanced production equipment, such as CNC vertical lathe, Hangzhou crane, milling machine, boring machine and other equipment, but also 16 professional and technical personnel. At the same time, we also have advanced production technology. Shenyang Shanyou has been engaged in manufacturing mining machinery and equipment for 27 years. We are strict with ourselves to ensure that every product produced meets the factory requirements and customer requirements. We will carry out quality control on every detail, So as to produce high-quality machinery and equipment.