- Home

- >

- Products

- >

- metso Copper Parts

- >

Factory Introduction 🔗

Shenyang ShanYo Heavy Mining Machinery Co., Ltd is a comprehensive industrial and trade enterprise

specializing in the production, sales and service of wear-resistant accessories for crushing equipment.

Shenyang ShanYo specializes in the production and research and development of high manganese

steel wear-resistant castings, with an annual production capacity of 25,000 tons. The factory was

established in 1996 and is located in Shenyang City, Liaoning Province. It covers an area of 40,000

square meters. It has two intermediate frequency furnaces, three heat treatment furnaces, and 10

lathes. It can cast the largest piece weighing up to 10 tons and the largest size is 3 meters × 3 meters.

×3 meters.

Based on advanced production equipment and complete testing technology, Shenyang ShanYo

has ISO9001, ISO14001, ISO45001 and other certifications, and has dozens of utility model patents.

The registered trademark Shenyang ShanYo enjoys a high reputation among domestic peers

and has always been in a leading position in the Central and South China regions.

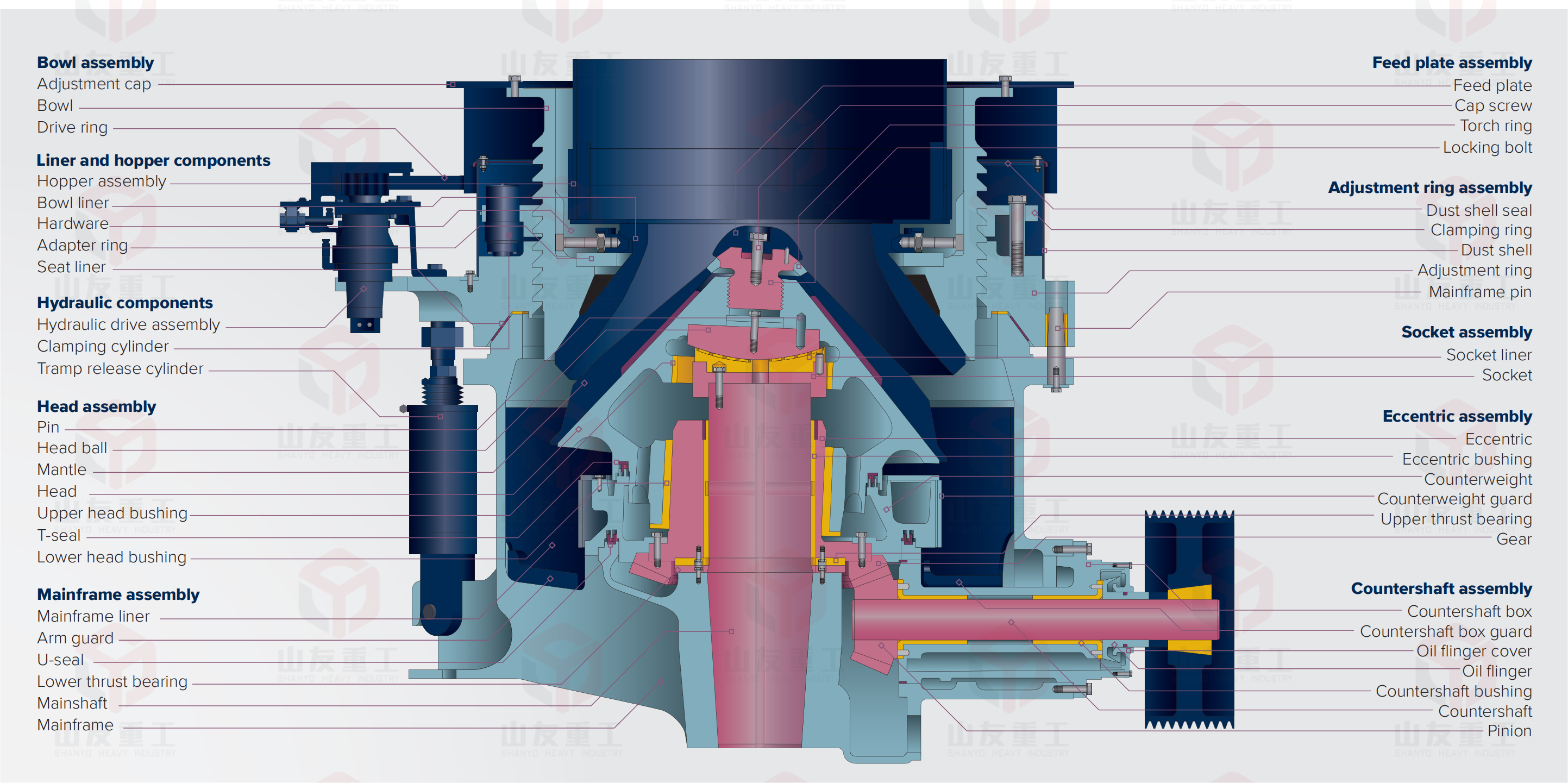

The main products include: cone crusher parts (cone lining plates, pressure sleeves, cutting rings, etc.);

jaw crusher accessories (jaw plates, side fender, pressing blocks, etc.); ball mill accessories (ball mill

lining plates, grating plates, steel balls,etc.); impact crusher accessories (blow hammer, liner, etc.).

Shenyang ShanYo provides high-quality accessories and services to famous mining machinery ,

has accumulated rich practical experience, and has established long-term cooperative relationships

with many domestic crusher manufacturers.

The products are sold all over the country and exported to the United States, Russia, Australia, Japan,

Thailand, Mongolia and other countries and regions, and are well received by users at home and abroad.

Production equipment 🔗

The main equipment of our factory includes five-meter CNC vertical lathe, slotting machine, three-zero lathe, eight-point rocker, Hangzhou crane, 160 boring machine, internal milling machine and other equipment.

There are large and medium sized Vertical lathe 125、80、60、20Horizontal lathe 160、90、60 Floor type borer 100、80、50 Radial drill Various processing 40 equipment.

In the processing of production, not only to the high quality can be ensured by reasonable arrangements, as well as a high efficiency, all equipment including vulnerable parts,spare parts,product parts are processed by our own production.

Ongoing Feedback Service

ShanYo is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude ShanYo makes it a point that past sales are just as important as the future. Because of this ShanYo will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.

Our goal is to provide minining equipment of excellent quality and reliability, in order to establish a reputation and relationship with our customers which will keep them customers for life.

We have a strict quality control system in place throughout the entire production process, so our products are all of the highest quality and reliability.

If you have a need for any mining equipment, or related spare parts, please feel free to contact us. We are dedicated to serving each of our customers to their complete satisfaction.

Packing of Cone Crusher Parts 🔗

Our company uses wooden cases for packaging and plastic film to reinforce the packaging to ensure that the products can be delivered to customers in good condition.

FAQ 🔗