Working principle of ball mill machine

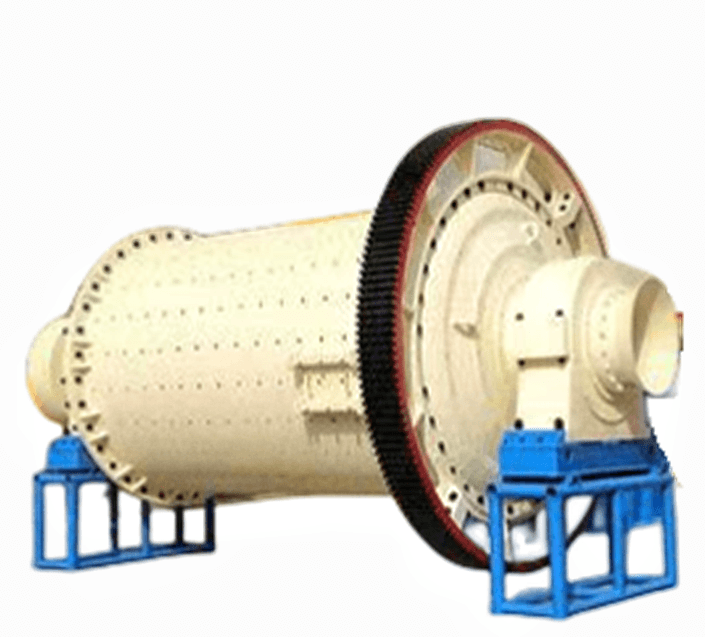

1. Working principle of overflow ball milling machine

The working principle of the overflow ball mill is mainly supported by the rolling bearing. The transmission device is used to drive the cylinder to rotate, so that the material and steel ball and the cylinder are rotated together, and the tubing, impact, impact and self -grinding operations are completed in the cylinder to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the material to achieve the materials to achieve the material grinding. In the case of continuously giving the material, it will be under pressure, and the material in the tube is gradually discharged to the discharge end. When the slurry is higher than the lower edge of the empty axis at the middle of the ore end, the material will overflow from the flow, and the steel at the end of the ore is steel. The ball and coarse material will be returned from the anti -spiral blades to the grinding machine, and the grinding is continued.

2. Working principle of plaid ball mill machine

The working principle of the grid ball mill is roughly similar to the overflow type. The rotation of the cylinder drives steel balls and materials for parabolic operations. In the process, it achieves impact, grinding, and crushing operations. The difference is that the lattice plate is equipped with a plaid board for the ore of the grid ball mill, which is installed in the end cover of the hollow neck at the end of the mining end. It consists of eight radioactive tendons. The lining plate is fixed inside the fan -shaped room, and the grid lining plate is installed on the fan -shaped room. Among them, there is an inverted trapezoidal pores on the grid lining plate. The ore grain that meets the granularity requirements during the grinding process will enter the fan -shaped room with the gap of the grid board. The room wall flows into the middle of the air, and the crushing process is completed through the gentium -empty -necked ball mill.

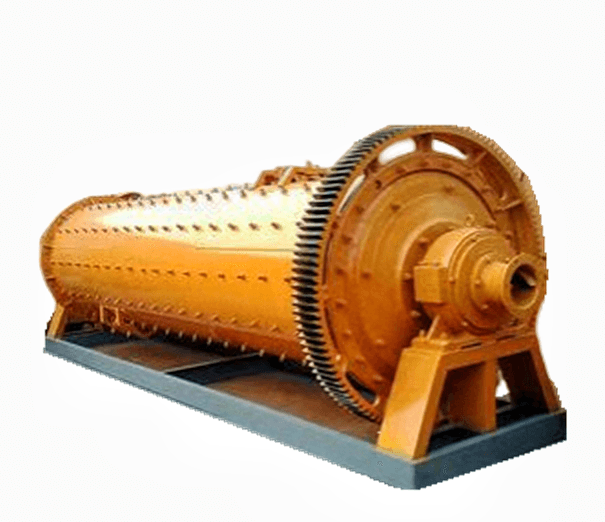

3. Working principle of horizontal ball mill

The appearance of the horizontal ball mill is a horizontal cylindrical rotation device, which is driven by the gear, sprocket or belt. It is different from the grid and the spill ball mill. There are two material warehouses. When the cylinder starts to rotate, the material is loaded into the tube body from the feeding end of the feed, which is used in the common effect of inertia and centrifugal force and friction. The material spiral through the feeding device in the feed device is uniformly entered the first warehouse of the abrasive machine. The warehouse has a ladder lining plate or a ripple lining plate, and a steel ball of different specifications is built. After a certain height, it fell to attack and grind the material. After the material reaches rough grinding in the first warehouse, the single -layer compartment board enters the second warehouse. The cabin is inlaid with a lining plate with a steel ball inside. Raunted out of the raw end and complete the powder operation.

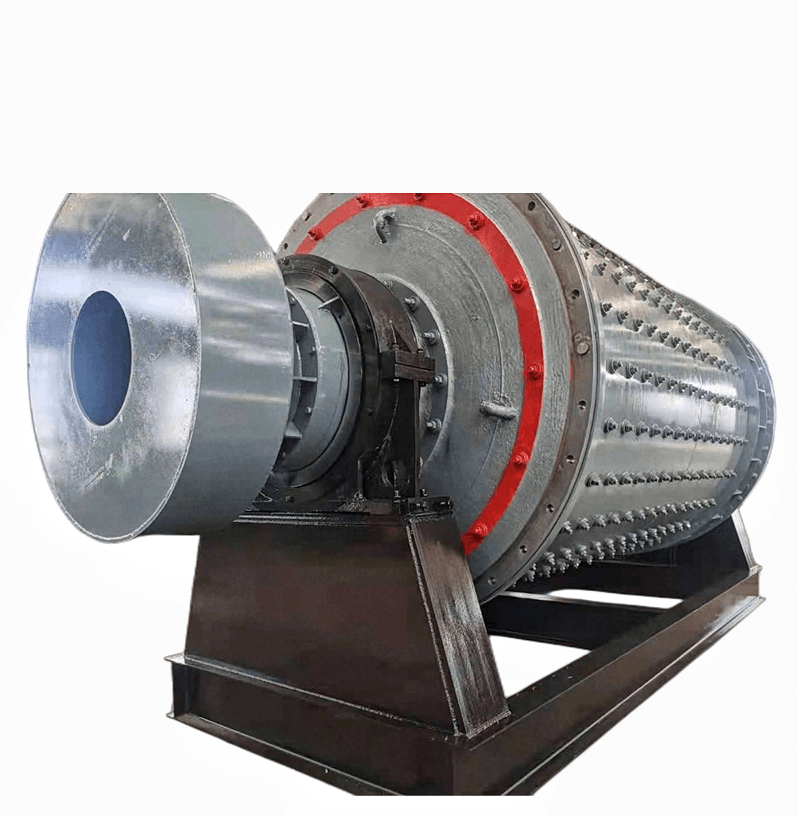

4. Working principle of conical ball mill

The cone mill grinding machine is similar to that of the horizontal ball mill, which is also driven by the outer gear, the two warehouse types, the same principle, but the two warehouses of the conical ball mill are inlaid with a lining plate. Remove the grinding plate and complete the grinding.

5.Planet ball mill working principle

The planet ball mill is equipped with four ball mills on the same turntable. When the turntable rotates, the ball mill tank will pass on its own axis at the same time as the axis, and the ball in the can. , Grinding and mixed materials.