About Us

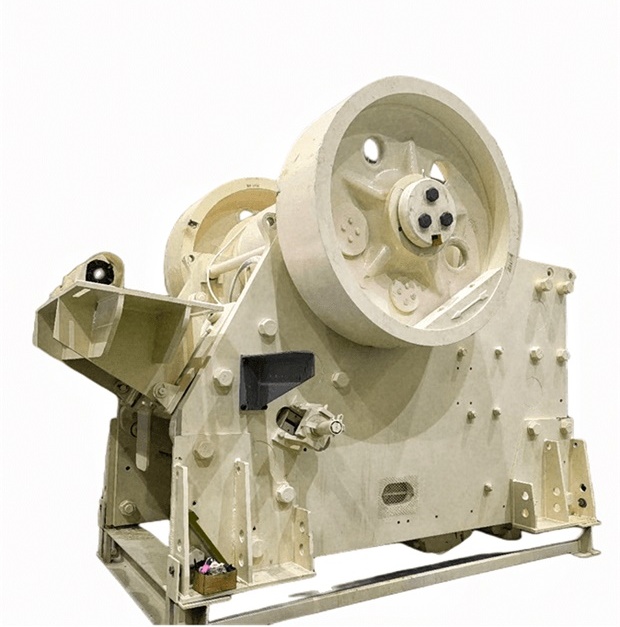

The jaw crusher is a rough and broken device in the mining industry, which plays a very important role in the production line. It can shatter large hard materials such as quartz stones, bluestone, river pebbles, pebbles, limestone, iron ore and other stones. Because of its reliable operation, simple operation, and convenient maintenance, it is welcomed by the majority of mining merchants.

The crushing method of the jaw crusher is curve extrusion, and its working principle is to simulate the jaw movement of animals. When working, the motor drives the belt and pulley through the eccentric axis to move the jaw up and down. When the jaw rises, the angle between the elbow plate and the jaw becomes larger, thereby pushing the jaw plate to approach the fixed jaw plate, and the materials are crushed multiple times through the squeezing, friction and grinding between the two jaw plates. When the jaw decreases, the angle between the elbow plate and the jaw becomes smaller, and the motion jaw leaves the fixed jaw plate under the action of the trolley and spring. The fragmentation is freely discharged through the outlet of the lower part of the jaw under the action of gravity. With the continuous rotation of the motor, the dynamic jaw is crushed and discharged cyclical, and mass production is achieved.

The structure of the jaw crusher:

The jaw crusher is mainly composed of racks, fixed jaw panels, mandibular boards, guards, transmission parts, adjustment seats, mandibular stalks, etc. Jaw crusher structure

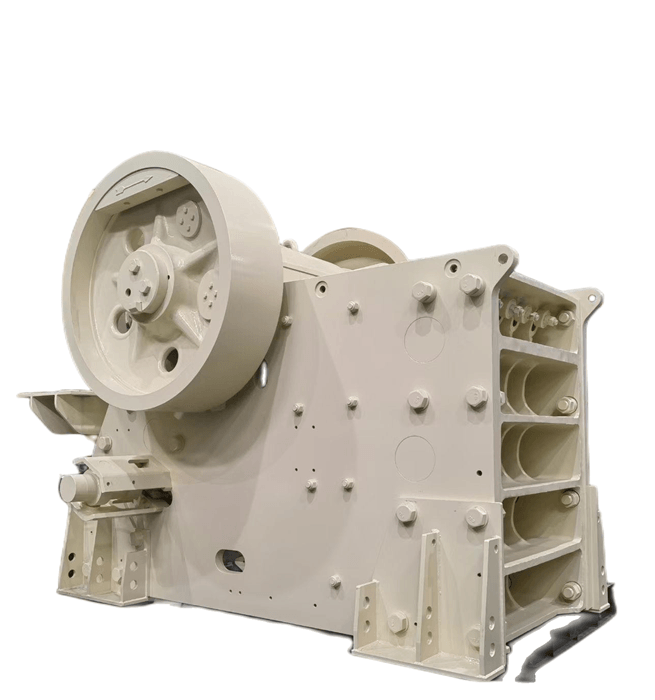

The frame is a rigid stand on the wall of the upper and lower openings, which is used to support the eccentric axis, and to withstand the reaction force of crushing materials. It requires sufficient strength and stiffness. Generally, cast steel is cast as a whole, and the small machine can also be replaced by high -quality cast iron instead of cast steel. The framework of the host needs to be cast in sections, and then uses a bolt to be firmly connected into a whole, so the casting process is complicated. The rack of homemade small jaw crusher can also be welded with thick steel plates, but the rigidity is poor.

Jaw and side guard

The fixed clamp mouth and the active kit are composed of the clamp mouth and the lip plate. The lip plate is a working component, and it is fixed on the clamp seat through the bolt and wedge iron. The fixed jaw bed is the front wall of the rack. The mobilizer bed is hung on the circular. It requires sufficient strength and stiffness to bear the crushing reaction, so most of the cast steel or cast iron parts.

Transmission Parts

The eccentric axis is the main axis of the crusher, which is made of high -carbon steel. Eccentric parts should be performed and thermal treatment should be performed, and the bearing lining should be cast with Pakistan alloy. One end of the eccentric axis is equipped with a belt wheel, and the other end is equipped with a flywheel.