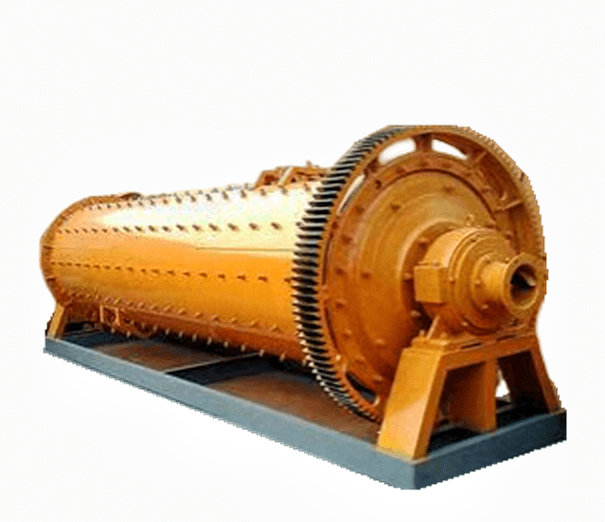

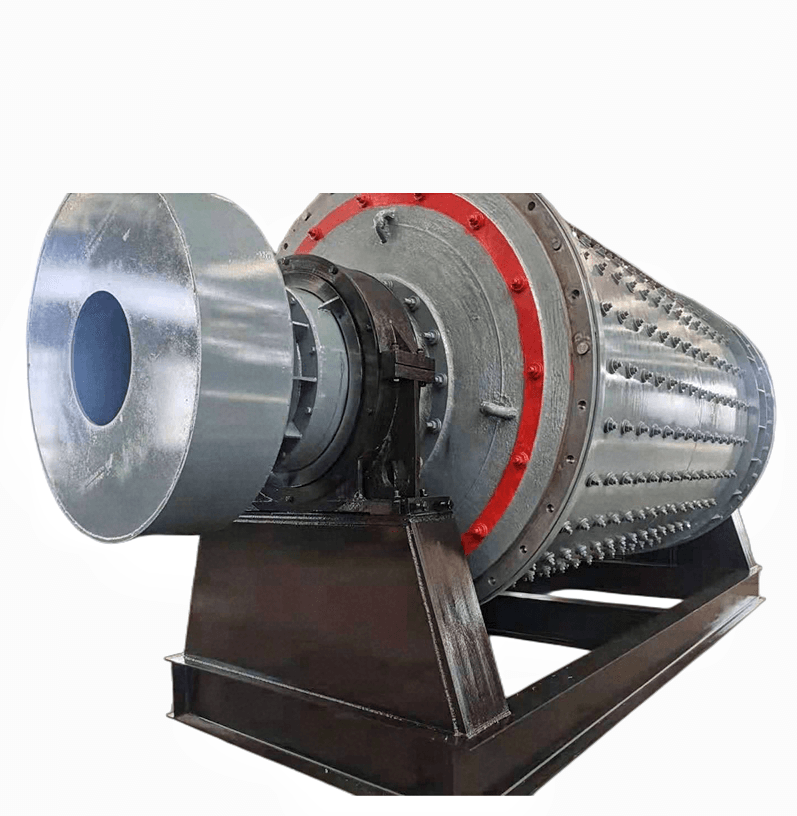

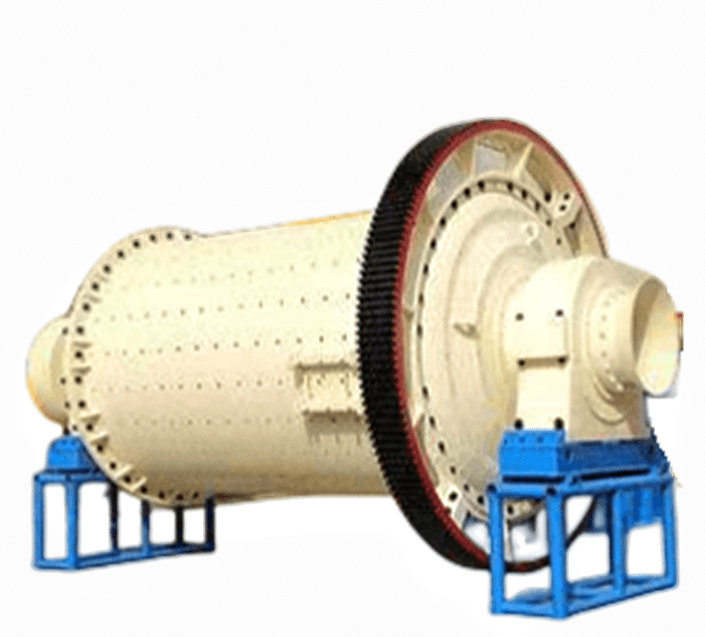

The ball mill is a key device for crushing after the material is broken. It is widely used in the production industries such as cement, silicate products, new building materials, refractory materials, fertilizer, black and non -ferrous metal minerals, and glass ceramics. Various ore and other abrasive materials are grinded with dry or wet powder. The ball mill is suitable for all kinds of ore and other materials for powder grinding. It is widely used in minerals, building materials and chemical industries, and can be divided into two types of abrasive methods: dry and wet -type milling methods. Depending on the method of excretion, the grid type and overflow type can be divided.

The ball mill is composed of a horizontal cylinder. The inlet and outlet of the air axis and grinding head are composed. The cylinder is long cylindrical. The tube is equipped with a grinding body. The cylinder is made of steel plate. Generally, it is a steel ball, and the grinding body can also be used in different diameter and a certain proportion. The grinding body can also be used.

According to the granular size of the grinding material, the material is loaded into the tube body from the element of the ball mill inlet. When the spherical grinding machine is rotated, the grinding body is attached to the cylinder lining plate due to the effect of inertia and centrifugal force and friction. When the cylinder is taken away, when it is taken to a certain height, it is thrown off due to its own gravity effect.

The material is uniformly entered the grinding machine's first warehouse from the air -in -shaft spiral spiral in the feed device. The warehouse contains a ladder lining plate or a ripple lining plate. After the height falls, it has a blow and grinding effect on the material. After the first warehouse reaches the rough grinding, the single -layer compartment board enters the second warehouse. The warehouse is inlaid with a lining plate with a steel ball inside, and the material is further grinded. Powder is discharged through the unloading panel to complete the powder grinding operation.

In the process of turning in the cylinder, the grinding body also slipped. During the sliding process Use the barriers to separate into two sections, that is, it becomes double warehouse. When the material enters the first warehouse, it is crushed by steel balls. When the material enters the second warehouse, the steel segment is grinded by the material. When the shaft is discharged, the material of the feed particles is grinded, such as sand 2 slag, coarse flour and coal ash.

The raw material is grinded by the empty heart cylinder through the hollow neck, and the cylinder is equipped with a variety of diameter grinding medium (steel ball, steel rod or gravel, etc.). When the cylindrical horizontal axis rotates at a certain speed, the medium and raw materials installed in the cylinder are under the influence of centrifugal force and friction. As the cylinder reaches a certain height, when its own gravity is greater than the centrifugal force, it is out of the cylinder. The wall of the body ejaculates or rolled down, crushing ore due to impact force. At the same time, during the grinding machine rotation, the sliding movement of the abrasive medium also has a grinding effect on raw materials. The grinding materials are excreted through hollow -up necks.

The ball mill consists of the main part of the material department, outbestion department, transfer department, transmission department (reducer, small transmission gear, motor, electronic control). The hollow shaft is used for cast steel parts, the inner lining is removed, and the large gear is processed by casting the large gears. The inlaid of the tube is inlaid with wear -resistant lining plate, which has good wear resistance. This machine is running smoothly and reliable work.

The ball mill host includes a cylinder. The tube is inlaid in the linings made of wear -resistant materials. It has a bearing bearing and maintaining its rotating bearings. There is also a driving part, such as the motor, the transmission gear, the belt wheel, the triangular belt, etc.

Regarding the parts called blades, it is generally not the main part. There is an inner spiral in the feed inlet of the inlet of the intake end. It can be called the inner spiral blades. There is an internal spiral in the port of the material at the part of the material.

In addition, if a spiral transport aircraft is used in the auxiliary device at the outbound end, there will be parts called spiral blades in the device, but strictly speaking, it is no longer a part of the ball mill.

According to the material and ore discharge methods, you can choose a dry ball mill and a wet format ball mill. Energy -saving ball mill, automatically adjustable double -row towards the heart spherical roller bearings, with small operating resistance and significant energy -saving effect. The tube part is added to the original tube bodies to add a section of cone cylinder, which not only increases the effective volume of the mill, but also makes the medium distribution of the tube more reasonable. This product is widely used for crusting for non -ferrous metals, black metals, non -metal mining places, chemical and building materials industry.

(1) Increase the effective volume

The effective volume of the abrasive machine can increase the grinding capacity year -on -year, thick lining, large weight, increased power consumption, reduce the effective volume of the cylinder, and reduce the production efficiency of the ball mill. If the magnetic lining plate is selected, the effective volume of the cylinder can be increased, the weight is relatively reduced, and the power consumption is reduced. However, there are certain disadvantages to choose a thin magnetic lining plate. Due to the small thickness, the anti -strike ability is not as good as the current CR one MN, one MO alloy casting steel lining plate, which is prone to rupture problems. For example, for the lining problem, some manufacturers use groove -type ring lining plates to increase the surface of the ball ore contact surface, strengthen the grinding effect, and improve the ore, reduce energy consumption, and be widely used.

(2) Increase the fill rate and rotation rate

The processing capacity of the ball mill has increased with the filling rate of steel balls, increasing the filling ratio and increased the probability of steel ball crushed milling ore and ore self -grinding effect. When the steel ball filling ratio is the maximum of the ball grinding machine at 45%, the load increases significantly with the increase of the filling ratio when it exceeds 45%. This is mainly because with the increase of the filling rate, the throwing point of the steel ball is raised, and the impulse of the steel ball has accelerated to approach and surpasses the center of the rotary. The load required for the impact torque of its steel ball (including ore) to fall from large to 0 from large to 0 until it becomes the power to promote the rotation of the cylinder (that is, the point of the joint force exceeds the center, and the torque is negative).

(3) Change the shape of the grinding minerals

The oval ball medium can be selected instead of the current spherical medium. Compared with the spherical ball, the advantages are as follows:

Compared with the spherical sphere, the ellipse body can greatly improve the crushing and grinding capacity of the ball mill, and at the same time, the device loss is also reduced accordingly.