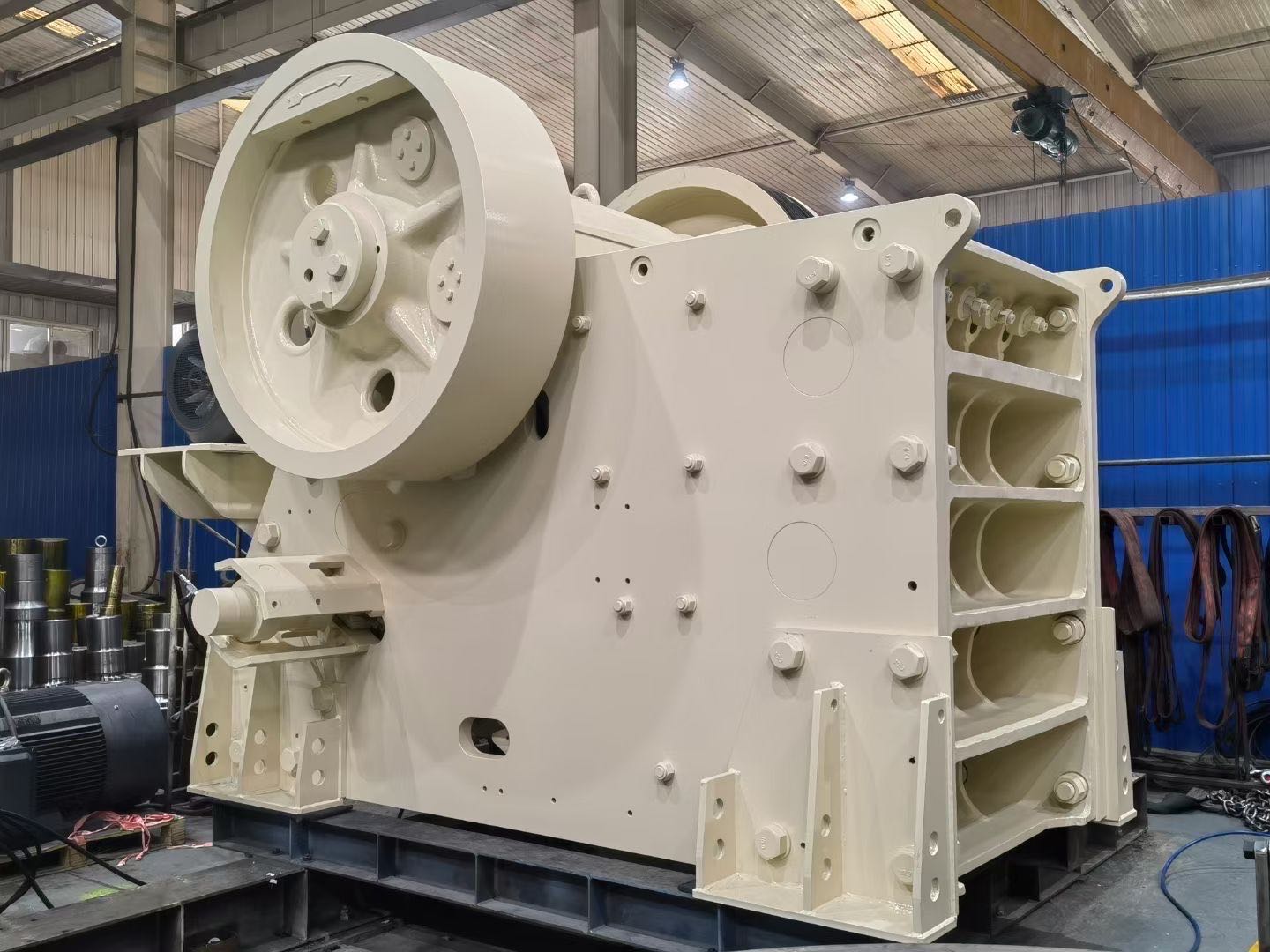

Jaw Crusher Wear Causes and Solutions

For the jaw crusher, we all know that his most important working parts are composed of two jaw plates: the movable jaw and the static jaw. The movable jaw breaks against the impact of the static jaw plate to do reciprocating motion, separate the finished product from the lower part of the discharge; close to the material is crushed by the extrusion and crushing. After understanding the working principle of jaw crusher, it is easy to understand the wear and tear of jaw crusher.

The jaw crusher tooth plate is made of water-toughened standard high manganese steel. Its tooth plate wear belongs to cutting type wear. After analyzing, this cutting wear is mainly divided into three cases:

1、the repeated extrusion of materials, resulting in dental plate surface material is partially cracked or turned up, and its cracked or turned up part of the material with the extrusion of the impact together with the shedding of the formation of debris.

2、Materials repeatedly extruded and cut the dental plate, the surface of the dental plate, or in the root of the prominent part of the dental plate to form small cracks, these small cracks continue to expand to the connected, resulting in the surface of the dental plate material shedding, the formation of debris.

3、Materials relative to the tooth plate short-range sliding friction, friction cutting tooth plate to form debris, resulting in tooth plate wear.

Therefore, to control the wear of jaw crusher tooth plate and extend the service life of the tooth plate, the main consideration is the hardness and toughness of the tooth plate material. High hardness of tooth plate material, wear resistance, strong resistance to extrusion, reduce the tooth plate in the process of extrusion and impact with the crushed material brittle fracture, reduce the tooth plate surface deformation and cracking.

So when we buy jaw crusher jaw plate, we must choose the jaw plate made of high hardness and wear-resistant material. The jaw plate must be installed tightly, and if necessary, a layer of good plastic material can be padded between the jaw plate and the surface of the crusher.