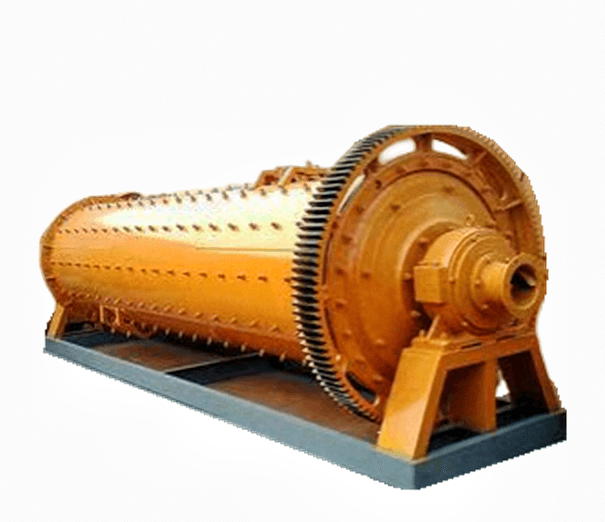

Ball mill in the work of noise, if the noise is too large, will affect the nearby residents. Equipment noise problem has been bothering many users, so how to solve it. Below we will look at the ball mill noise reasons.

1.The noise of the ball mill is related to the diameter and speed of the ball mill, as well as the properties and lumps of the materials.

2. The noise of ball mill is basically a kind of steady-state noise with wide frequency band and high acoustic energy of low, medium and high frequency components. The larger the diameter of ball mill is, the stronger the low frequency component is.

3. The noise of ball mill is mainly the mechanical noise caused by the impact of metal ball, liner and the processed material. The sound of the ball mill radiates outward along the bush, cylinder wall, inlet and outlet. The ball mill includes the impact sound between the steel ball and the steel ball, the impact sound between the steel ball and the lining steel plate, the impact sound and the friction sound of the material. The noise caused by the vibration of the driving mechanism of the ball mill when other equipment in the ball mill is running.

It is inevitable that the ball mill will produce noise in the course of running. The noise will bring unnecessary trouble to the workers, even endanger their health. Therefore, the ball mill noise control can not be ignored, then how to reduce the ball mill noise it.

1.In order to reduce the noise produced by Ball Mill, engineers and technicians take various measures. Noise enclosure or sound insulation material is one of the important means to control the noise of ball mill. The noise enclosure installed around the ball mill can effectively reduce the transmission and diffusion of noise. At the same time, the ball mill can also be wrapped with sound insulation material to reduce its vibration and noise.

2.Optimize the technological process of ball mill. The noise of ball mill is closely related to its process flow. Therefore, optimizing the ball mill process is also an important means to reduce noise. For example, by designing the inlet and outlet of the ball mill reasonably, the impact and friction to the granular materials can be reduced, thus reducing the generation of noise.

3. Using low noise equipment, the structure and design of the ball mill itself will also have an impact on the noise. Therefore, the use of low-noise equipment is one of the effective measures to reduce the ball mill noise. For example, the use of low-noise motor and reducer can effectively reduce the machine vibration and noise.