About Us

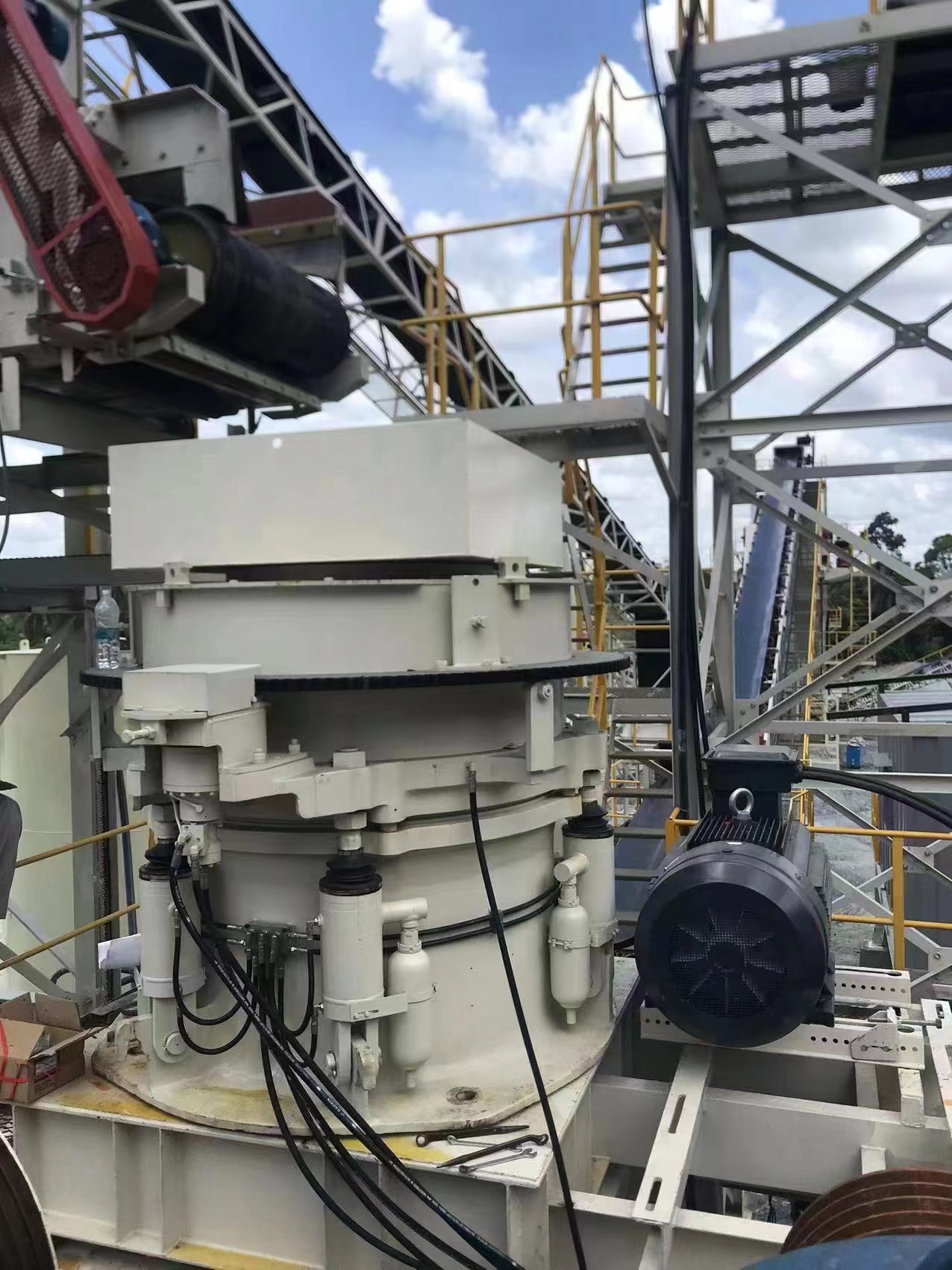

Cone crusher is a crushing machine with finer crushing particle size than jaw crusher and impact crusher, and larger crushing particle size than sand making machine and grinding machine. Located in the final stage of the ore crushing production line and in an important position, it is also a key equipment of the beneficiation plant.

Working principle of cone crusher

The cone crusher mainly relies on impact energy to complete the crushing of materials. When the cone crusher is working, the motor drives the rotor to rotate at high speed, and the material evenly enters the crusher chamber. The high-speed rotating hammer head impacts, cuts and tears the material, causing it to be crushed.

In the production line of general industries, when the cone crusher performs the fine crushing process, the gravity of the material itself causes the material to rush from the high-speed rotating hammer head to the baffle inside the frame, and the sieve bar. Materials larger than the sieve hole size are blocked from staying on the sieve plate and continue to be hit and ground by the hammer until they are broken to the required discharge particle size and finally discharged through the sieve plate outside the machine.

Classification of cone crushers

According to the scope of use, cone crushers are divided into three types: coarse crushing, medium crushing, and fine crushing. Coarse crushing cone crushers are also known as rotary crushers, and medium crushing and fine crushing cone crushers are also known as mushroom shaped cone crushers.

The rotary crusher is a type of coarse crushing equipment, mainly used in the mineral processing industry and other industrial sectors for coarse crushing of ores with various hardness. The mushroom crusher is mainly used as a medium and fine crushing equipment for various hardness ores. Based on the current situation in the crushing workshops of mineral processing plants in China, most of the intermediate crushing equipment uses standard cone crushers, while the fine crushing equipment mostly uses short head cone crushers, which have almost been finalized. However, the coarse crushing equipment either uses a rotary crusher or a jaw crusher.

Performance characteristics of cone crusher

1. The perfect combination of high-performance crushing chamber type and high crushing frequency greatly improves the processing capacity of the cone crusher. Additionally, due to the use of the laminated crushing principle, the crushing products are mostly cubic in structure, greatly reducing the number of needle like materials.

2. The cone crusher has a simple structure, which is easy to operate and maintain. The adjustment of the discharge port is convenient and fast, saving time and effort during maintenance. Especially, the lining plate is easy to replace quickly, reducing downtime.

3. When an unbreakable foreign object passes through the crushing chamber or the machine is overloaded for some reason, the spring safety system of the cone crusher achieves safety, and the discharge of ore from the cone crusher increases. Foreign objects are discharged from the crushing chamber of the cone crusher. If foreign objects are stuck at the ore discharge port, a cleaning system is used to increase the ore discharge and allow foreign objects to be discharged from the crushing chamber of the cone crusher. Under the action of the spring, the cone crusher automatically resets the ore discharge port, and the cone crusher machine returns to normal operation.

Application scope of cone crusher

1. It can be used in crushing production lines, sand production lines, and high-speed rotating hammer bodies that collide with materials to crush materials. It has the characteristics of simple structure, high crushing ratio, and high production efficiency.

2. Used for crushing various medium hard and weakly abrasive materials, with a compressive strength not exceeding 100MPa and a moisture content less than 15%. The crushed materials are coal, salt, gypsum, bricks, tiles, limestone, etc.

3. Used for crushing broken wood, paper, or asbestos cement waste with strong fiber structure, elasticity, and toughness to recover asbestos fibers.

Daily maintenance of cone crusher

1. Pay attention to frequently adjusting the discharge gap

As the crushing time accumulates, the wear of the crushing lining plate will increase, the particle size of the crushing product will change, and the crushing power consumption will also increase. Therefore, it is necessary to regularly adjust the discharge gap and keep it within an appropriate range to ensure that the crusher is always in a good crushing effect.

2. Strengthen lubrication work

The lubrication of the cone crusher mainly prevents the wear of key motion pairs such as the moving cone and its support seat, the main shaft and its sleeve. Choose the appropriate lubricating oil to ensure the appropriate oil pressure and supply quantity; Regularly and quantitatively add lubricant to prevent water and dust from polluting the lubricated parts; Replace the lubricant promptly after a certain period of use or deterioration.

3. Hydraulic cone crusher should ensure the reliability of hydraulic components

Due to the fact that hydraulic components are precision components, it should be ensured that they are not contaminated by water or dust to prevent hydraulic oil leakage.

4. Regularly inspect all fasteners for looseness.

Cone crusher is one of the commonly used crusher equipment in mining equipment. Due to its high output and low energy consumption, it has become a key model of concern in the current crusher industry.