Cone Crusher,Spring Cone Crusher,Cone Crusher Medium Crusher

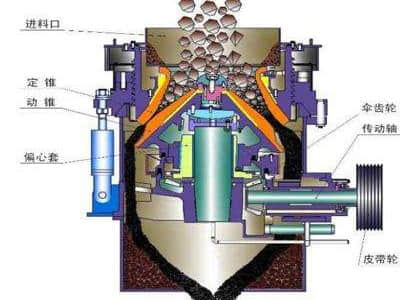

The cone crusher introduced here, spring cone crusher, if compared to the jaw crusher this kind of coarse crusher, can belong to the medium crushing of large and small particles of the equipment, therefore, we also often look at it as a medium crusher, also known as cone crusher crusher medium crusher. Cone crusher work, the rotation of the motor through the pulley or coupling, drive shaft and cone part of the eccentric sleeve under the compulsion around a fixed for the rotary pendulum movement, so that the cone crusher crushing wall from time to time close to and from time to time away from the fixed in the adjusting sleeve on the surface of the rolled white wall, so that the ore in the crushing chamber is constantly subjected to the impact, squeeze and bending effect to achieve the crushing of the ore.

Cone crusher maintenance points, cone crusher in the crusher maintenance need to pay attention to the aspects of

Cone crusher compared to other crushing equipment design is more complex, in the maintenance of maintenance also have some need to pay attention to small details, cone crusher life is usually longer, more durable, but the same price is higher, maintenance also need more maintenance skills. Here is a brief introduction.

1, the ore must be given in the middle of the distribution plate, not allowed to give the ore directly into the crushing chamber. Because this is easy to make the crusher overload, so that the liner wear uneven.

2, the output of the cone crusher, feed evenly when feeding, to avoid a one-time feed too much.

3、Replacement of molar wall.

4, the replacement of cone crushing wall.

5、Gear meshing.

6、Bowl bearing and sealing device.

7, cylindrical liner and frame for the third transition fit, in order to prevent the rotation of the liner, and in the upper groove of the liner injected with zinc alloy, replacement of the new liner should be made according to the actual size of the frame, because the crusher after a long period of time and loading and unloading will inevitably lead to changes in the relationship between the fit. If the clearance is too large will lead to bushing rupture.

8、Conical bushings and springs should be checked.

9, the exposed rotating part of the machine, should be added protective cover.

The introduction of cone crusher, spring cone crusher, cone stone crusher medium crusher is here for the time being. We here mainly will cone crusher principle, structure diagram, cone crusher maintenance attention aspects introduced out. Because the cone crusher is relatively speaking, the design and structure is more complex, therefore, the maintenance is a key work, the use of the process, although the crushing experience is better, but at the same time, it will also increase a certain maintenance costs. This is what the saying goes, everything has its advantages and disadvantages.