Cone crushers are divided into coarse crushing cone crushers (commonly known as rotary crushers) and medium and fine crushing cone crushers. The commonly referred cone crusher refers to a medium to fine cone crusher.

From the rotary crusher and cone crusher (as shown in the figure below), it can be seen that the former has a moving cone vertex above and a fixed cone vertex below, while the latter has both fixed and moving cone vertices above. This is because the feeding particle size of the rotary crusher is very large, requiring the crusher to have a larger feeding port.

Secondly, the bottom cone angle of the rotary crusher is very large, which is a conical shape. The cone crusher has a smaller bottom cone angle, which is a gentle cone type.

The rotary crusher is divided into two types based on the adjustment method of the discharge port and the support method of the dynamic cone: mechanical suspension dynamic cone and adjustment discharge port, as well as hydraulic support dynamic cone and adjustment discharge port. The former has currently ceased production. The latter is divided into bottom single cylinder and top single cylinder hydraulic rotary crushers.

According to different transmission methods, it can be divided into electric motors driven directly through transmission shafts and bevel gears; Dual motor drive (using two motors to work simultaneously during startup, only one motor is used during normal operation); The electric motor is driven by a hydraulic coupling; There are also transmission methods where the pulley is directly installed under the eccentric shaft sleeve. Transmission in early years abroad. But it is common to use electric motors through couplings and electric motors through belt drives.

Cone crushers are divided into two types based on the adjustment method of the discharge port and the different safety devices: spring type and hydraulic type cone crushers. There are three types of hydraulic cone crushers: multi cylinder hydraulic cone crushers, bottom single cylinder hydraulic cone crushers, and top single cylinder hydraulic cone crushers.

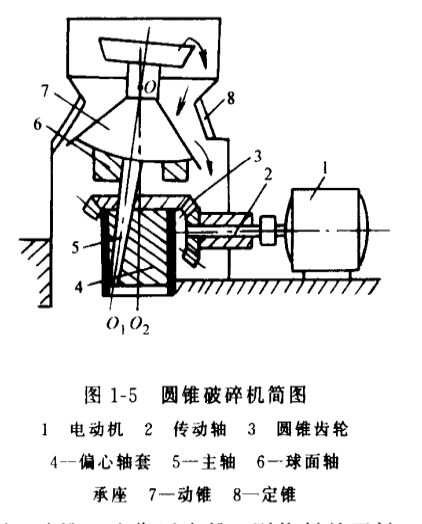

The working principle of a cone crusher is as shown in the following figure: the power of electric motor 1 is driven by 1, transmission shaft 2, and bevel gear 3 to rotate the eccentric shaft sleeve 4. The main shaft 5 is freely inserted into the tapered hole of the eccentric shaft sleeve 4. The moving cone 6 is fixed on the main shaft 5 and supported on the spherical bearing 7.